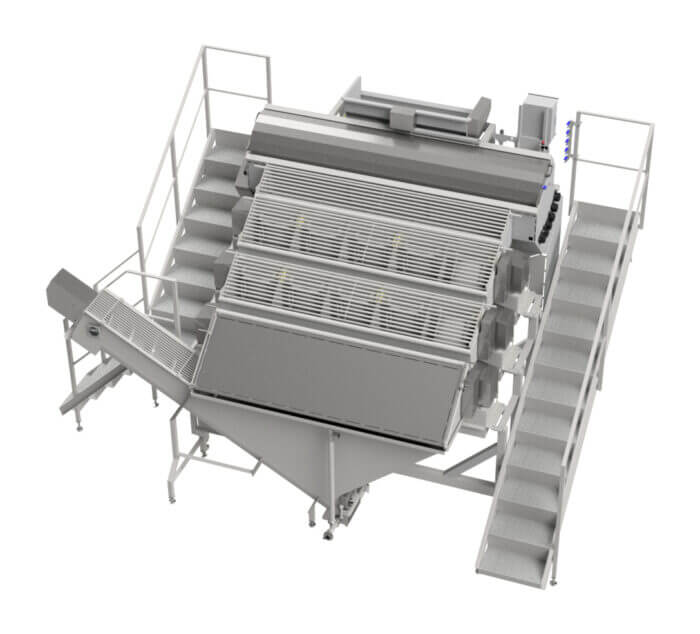

Knife Peeler

LIMAS Knive Peeler is a a fully integrated system comprising abrasive peeling steps followed by knife peeling steps, this model is very simple to operate and allows the user to fully optimise the benefits of the unique Limas knife peeling system.

The LIMAS Knife Peeler has a unique principle and construction. Designed to allow water-free peeling, the peeler is also compact but has a large capacity. It can be delivered with 1, 2 or 3 numbers of knife peeling steps to suit the capacity required. The product will always be pre-peeled by abrasive in one or more steps, until almost ready peeled, before they are passed onto the knife peeling step(s).

Advantages

- Superb high quality, hand-peeled appearance

- High yield

- Simple set-up and operation

- Low effluent cost

- Quick and easy knife replacement

Function

A Knife Peeling step comprises five peeling vessels. In the bottom of each is a rotating disc equipped with four knives. A counter/rotating stirrer makes sure that the potatotes have the optimun movement at a gentle speed.

Without moving the product too fast, a high cutting speed of up to 10 metres per second is achieved by the relative speed of the counter-rotating disc and stirrer. This ensures that a very smooth cut is produces without any hacking of incompete cuts.

Peeling times for both the abrasive and knife steps are independetly adjustable at the control panel, as are the speeds of the abrasive rollers, knife discs and the stirrers.

OPTIONS

- LIMAS Collection screw

- LIMAS Electronic weigher

- LIMAS Waste pump